Check out in which products you can find our aluminium.

Check out in which products you can find our aluminium.

Check out in which products you can find our aluminium.

Our Mission

As global experts in aluminum manufacturing, our mission is to drive the development of sustainable mobility and improve the quality of life for all of us with creative, smart and sustainable aluminum solutions.

2.500

Employees

6

Countries

240

Years of experience

550

Mio € Revenue (2024)

12

Plants

Our technologies

Casting

Impact Extrusion

Direct Extrusion

Profile processing and shaping

Markets

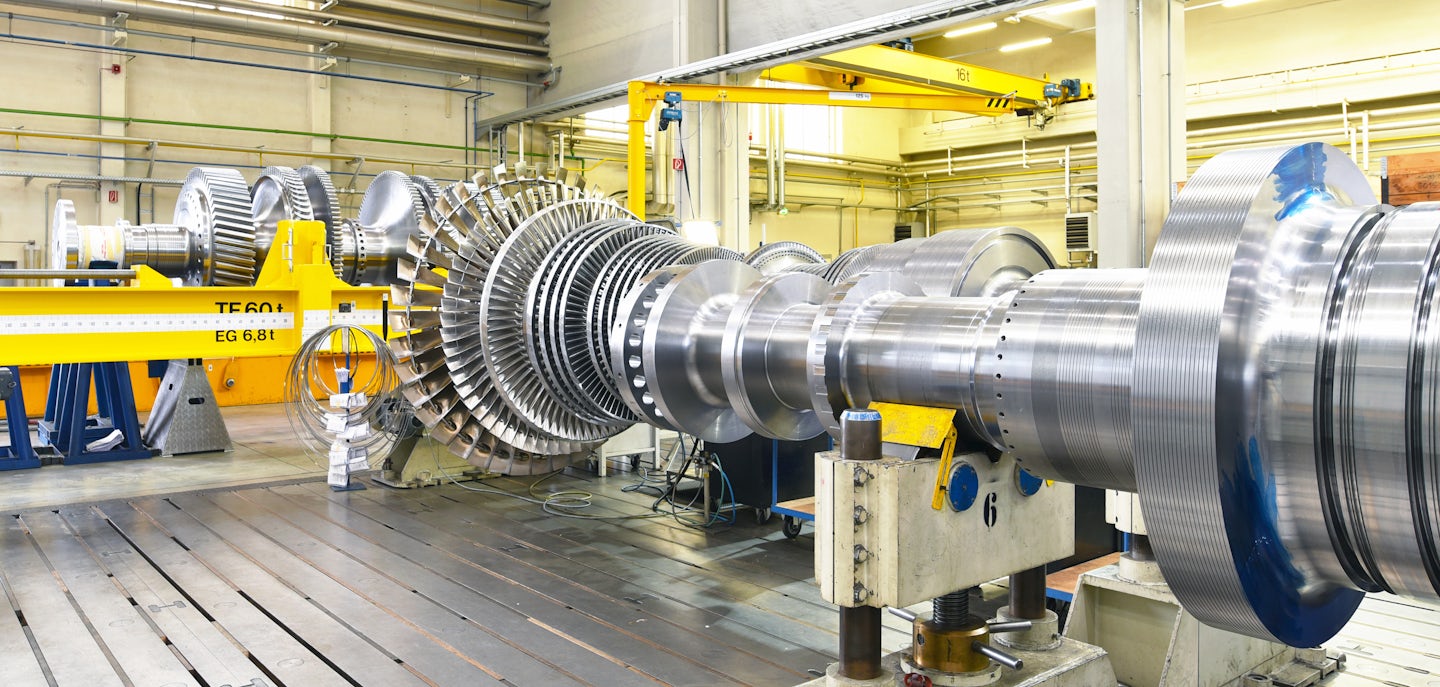

Mobility

E-mobility, chassis components, ADAS, system components, public transport, safety, roof opening systems

Products and markets

Construction industry

Roof, facade, windows, doors, garden, interior and office furniture

Products and markets

Packaging

Tubes, aerosol cans, lids and caps

Products and markets

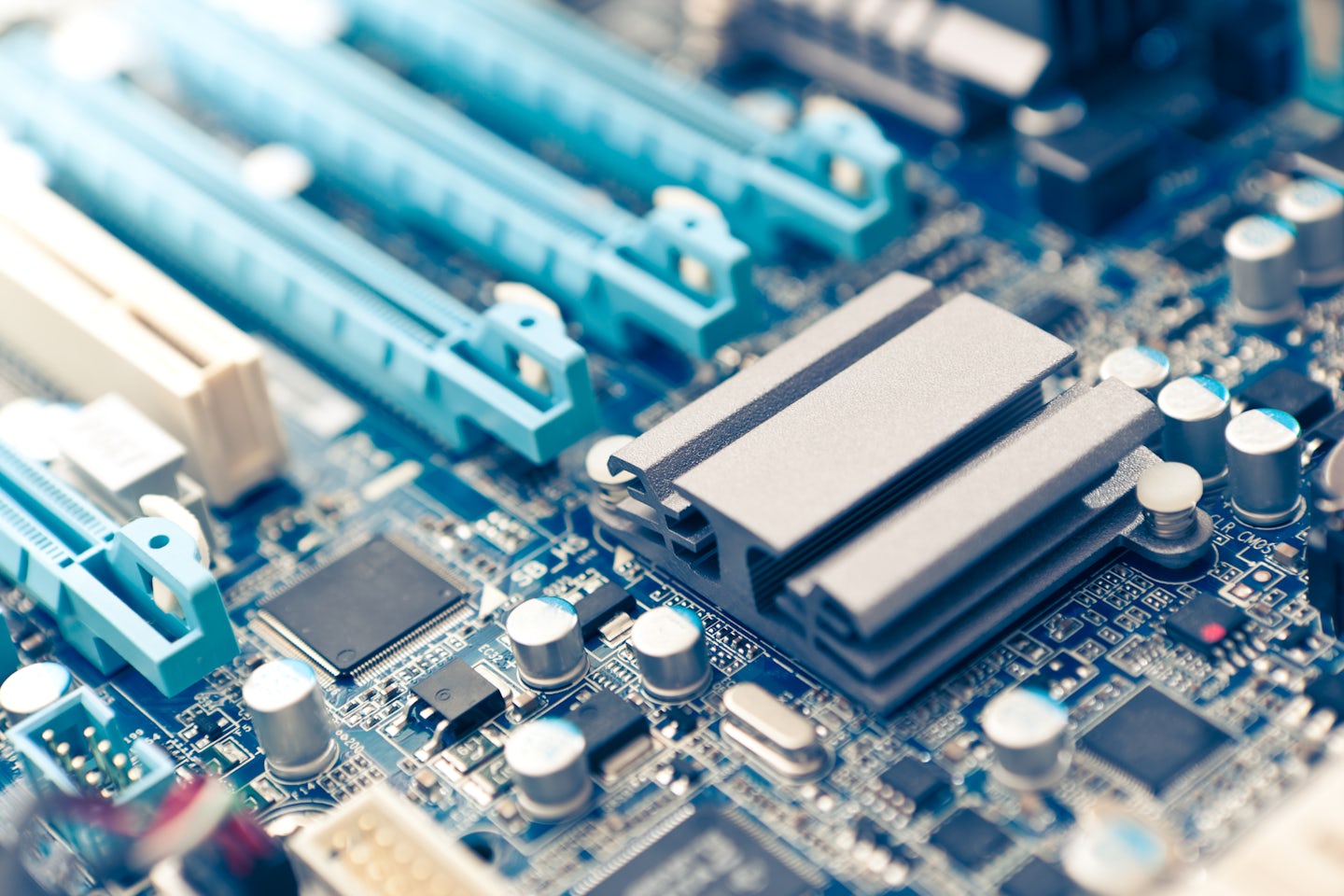

Electrical engineering

Heat sinks, lamp housings

Products and markets

Other industries

Mechanical engineering, medical technology, consumer goods, leisure goods, pyrotechnics and household goods

Products and markets

Our responsibility

Our responsibility

We are committed to reducing our CO₂ footprint and having a positive impact on society and the global ecosystem.

News

The Aluminum Valley: Marktl in Austria

The Aluminum Valley: Marktl in Austria

We stand for innovation, openness and collaboration. In collaboration with startups and visionary companies, we want to break new ground and find solutions for the challenges of the future. Join us and contact us!

Our team spirit leads to our customers’ success

A happy, motivated team makes a significant contribution to our customers’ satisfaction. Hence we always ensure a positive working environment, offer training, development opportunities and international career paths.

Events

Work for Neuman Aluminium

Become part of the Neuman family!