Impact extrusion

We have been technological pioneers of this cold-forming process for decades and are always on the lookout for new, exciting applications.

Don't feel like reading?

Advantages of impact extrusion

Efficiency of the manufacturing process

Impact extrusion uses almost exclusively mechanical knuckle-joint presses. They are significantly faster and more accurate than conventional hydraulic presses are. Impact extrusion with mechanical knuckle-joint presses is one of the most efficient manufacturing processes for medium- and high-volume parts. For small components, our knuckle-joint presses achieve cycle times of up to 330 strokes/minute while maintaining machine availability. Neuman Aluminium has the world’s largest mechanical knuckle-joint press with a maximum pressing force of 2,000 tons.

Strength and ductility

Aluminum impact extrusion is an aluminum cold-forging process. Plastic deformation at room temperature results in strain hardening effects, which are due to the movement of dislocations in the aluminum lattice. This is accompanied by an increase in strength and a simultaneous decrease in ductility. For higher material requirements, we can resort to customized heat treatment.

Tightness / free from blowholes

The impact extrusion process does not produce any blowholes or impurities in the components. Thus, our components can be used without hesitation as safety parts and as components for storing pressure media (gas-tight housings). This aspect also influences the further processing of components. While our impact-extruded parts are always smooth and free of porosities and craters after mechanical processing, in the casting process machining may open imperfections, leaving a pitted surface.

Forming tolerance

As aluminum is formed at room temperature during impact extrusion, no shrinkage occurs after the forming process. The shape tolerances of the finished part correspond exactly to those of the mold. Thus, in many cases no further processing steps are required.

Thin walls

Depending on the component size, very thin walls (down to less than 0.5 mm) can be pressed while maintaining the same mechanical properties. This leaves more installation space for the housing interior, which in combination with the high thermal conductivity is a strong argument in favor of the impact extrusion process.

Low tooling costs

Many customers are surprised by the comparatively low tooling costs. We are always working on ever more robust tools, which are manufactured in our in-house tool shop using state-of-the-art machine tools.

Advantages of impact extrusion

Efficiency of the manufacturing process

Impact extrusion uses almost exclusively mechanical knuckle-joint presses. They are significantly faster and more accurate than conventional hydraulic presses are. Impact extrusion with mechanical knuckle-joint presses is one of the most efficient manufacturing processes for medium- and high-volume parts. For small components, our knuckle-joint presses achieve cycle times of up to 330 strokes/minute while maintaining machine availability. Neuman Aluminium has the world’s largest mechanical knuckle-joint press with a maximum pressing force of 2,000 tons.

Strength and ductility

Aluminum impact extrusion is an aluminum cold-forging process. Plastic deformation at room temperature results in strain hardening effects, which are due to the movement of dislocations in the aluminum lattice. This is accompanied by an increase in strength and a simultaneous decrease in ductility. For higher material requirements, we can resort to customized heat treatment.

Tightness / free from blowholes

The impact extrusion process does not produce any blowholes or impurities in the components. Thus, our components can be used without hesitation as safety parts and as components for storing pressure media (gas-tight housings). This aspect also influences the further processing of components. While our impact-extruded parts are always smooth and free of porosities and craters after mechanical processing, in the casting process machining may open imperfections, leaving a pitted surface.

Forming tolerance

As aluminum is formed at room temperature during impact extrusion, no shrinkage occurs after the forming process. The shape tolerances of the finished part correspond exactly to those of the mold. Thus, in many cases no further processing steps are required.

Thin walls

Depending on the component size, very thin walls (down to less than 0.5 mm) can be pressed while maintaining the same mechanical properties. This leaves more installation space for the housing interior, which in combination with the high thermal conductivity is a strong argument in favor of the impact extrusion process.

Low tooling costs

Many customers are surprised by the comparatively low tooling costs. We are always working on ever more robust tools, which are manufactured in our in-house tool shop using state-of-the-art machine tools.

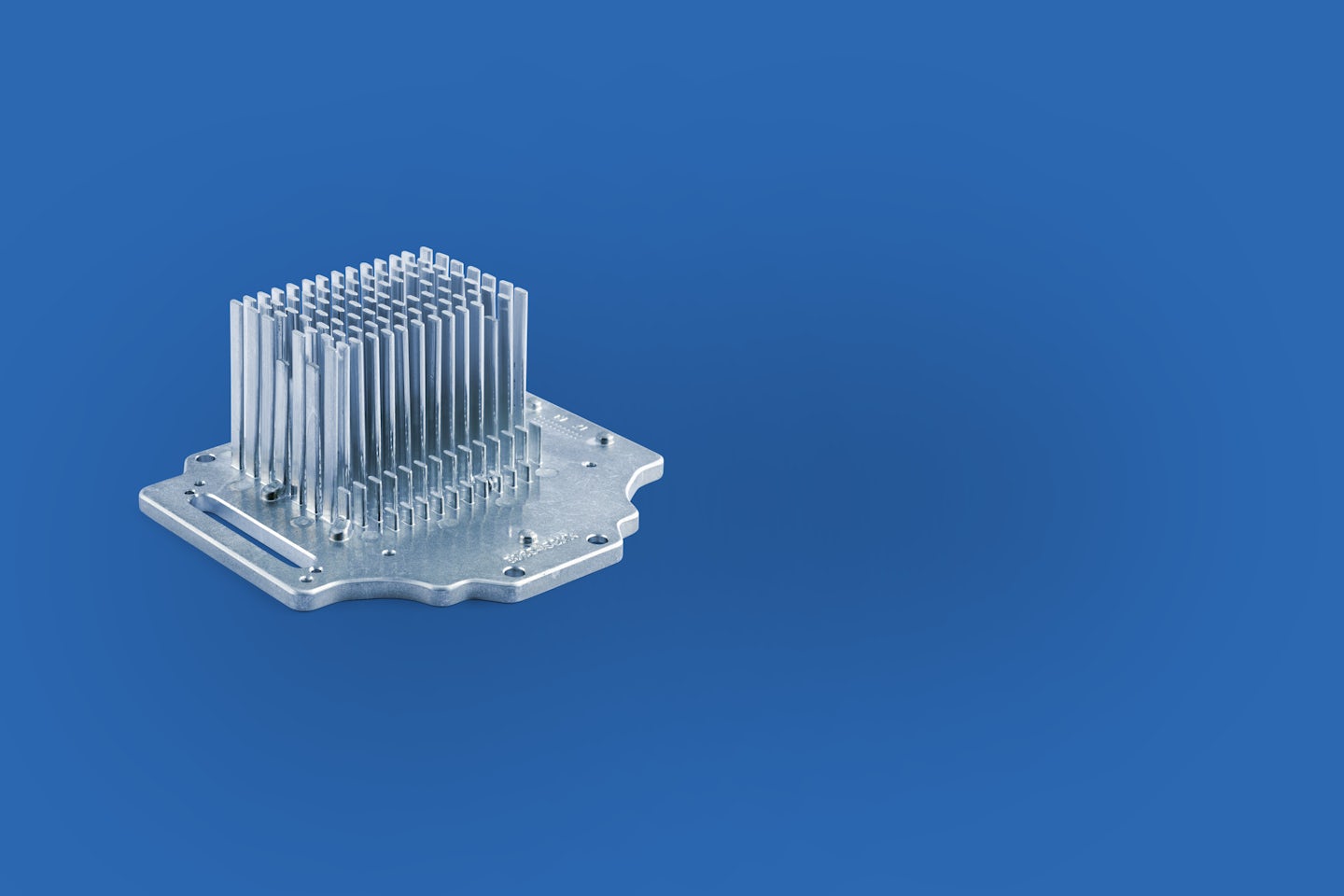

Heat sinks for power electronics

Heat sinks for power electronics

The heat sinks, made of pure aluminum using impact extrusion technology, have up to 30% higher thermal conductivity than a cast heat sink has, allowing components to be designed smaller and lighter. The cooling pins can be pressed in different lengths, round or star-shaped. The main application is in LED headlights, power electronics and control systems of modern cars and trucks.

The best solution

Alternative to deep drawing

For components with great length, with differences in bottom geometry compared to the wall, lower tooling costs.

Alternative to aluminum die casting

Thinner walls, no casting bevels, close tolerances, no shrinkage after cooling, low tooling costs, no voids and cavities, homogeneous microstructure.

Alternative to CNC milling / turning

Material saving, economically reasonable with increasing number of pieces.

Alternative to hot forging

Less weight, better surface properties for coating processes, more accurate tolerance limits, energy savings.

Innovation

Innovation

Thanks to the use of modern simulation software and our high level of expertise in the fields of materials science and toolmaking, complex geometries can be produced in medium and large series.

Industry solutions

E-mobility

Battery housing, motor housing, heat sink made of aluminum and copper

ADAS

Sensor housings, radar and camera housings, lidar components

Chassis components

Air spring components, joint fork, steering and brake elements, shock absorber

Safety

Airbag housing, micro gas generators, seat-belt tensioners, elements for brake

Electrical engineering

Heat sinks (aluminum and copper), LED lamp housings

Household and consumer goods

Miscellaneous housings, swash plate, elements for kitchen appliances, closures and lids

Enclosures and housings

Housings and enclosures for various application areas.

Watch John and find out how impact extrusions beats stamping and casting.

Value creation process:

1. Feedstock: Slugs

In impact extrusion, 90% of the slugs “pressed” are rectangular or round; often also perforated slugs are used. However, mold slugs can also be used without restrictions. Most frequently we process alloys of the 1000s (pure aluminum) and 6000s group (AlMgSi1 alloys). After consultation, other aluminum alloys can also be used; among others, we can also process copper and magnesium alloys. At the customer’s request, ultrasonic testing is performed on the feedstock at our suppliers’.

Value creation process:

1. Feedstock: Slugs

In impact extrusion, 90% of the slugs “pressed” are rectangular or round; often also perforated slugs are used. However, mold slugs can also be used without restrictions. Most frequently we process alloys of the 1000s (pure aluminum) and 6000s group (AlMgSi1 alloys). After consultation, other aluminum alloys can also be used; among others, we can also process copper and magnesium alloys. At the customer’s request, ultrasonic testing is performed on the feedstock at our suppliers’.

2. Impact extrusion

Using horizontal knee lever mechanical presses with press forces ranging between 150 and 1200 tons, we produce parts with lengths of up to 500 mm and an outer diameters of up to 150 mm – developed and improved upon the early 1900s.

3. Heat treatment

State of the art heat treatment facilities can achieve strength values of T4, T6 and T8 conditions, providing parts with the desired mechanical properties they require.

4. Machining and processing

We use flexible and efficient machines for machining impact-extruded parts, not only for large batches, but also for lesser quantities.

2. Impact extrusion

Using horizontal knee lever mechanical presses with press forces ranging between 150 and 1200 tons, we produce parts with lengths of up to 500 mm and an outer diameters of up to 150 mm – developed and improved upon the early 1900s.

3. Heat treatment

State of the art heat treatment facilities can achieve strength values of T4, T6 and T8 conditions, providing parts with the desired mechanical properties they require.

4. Machining and processing

We use flexible and efficient machines for machining impact-extruded parts, not only for large batches, but also for lesser quantities.

5. Surface treatment

We meet your surface requirements with our long-time partners.

6. Assembly & packaging

We assemble and pack your part according to your requirements either manually or through reliable, cost-effective automation.

7. Quality

Our comprehensive quality management system is completely integrated in the process flow. Our production is certified in compliance with: ISO 9001, ISO 14001, ISO 45001 und IATF 16949.

5. Surface treatment

We meet your surface requirements with our long-time partners.

6. Assembly & packaging

We assemble and pack your part according to your requirements either manually or through reliable, cost-effective automation.

7. Quality

Our comprehensive quality management system is completely integrated in the process flow. Our production is certified in compliance with: ISO 9001, ISO 14001, ISO 45001 und IATF 16949.

Locations and certifications

With our production facilities in Austria (Marktl), Slovakia (Žarnovica), Germany (Rottenburg), USA (Waynesboro, VA) and China (Xinhui) and our high level of on-site availability, a Neuman partner is always close by. We are certified according to the following standards: ISO 9001, ISO 14001, ISO 45001 and IATF 16949.

Work for Neuman Aluminium

If you want to make a real impact join Neuman Aluminium!