Direct extrusion

From innovative solutions around the house, garden and office up to complex applications for construction and industry, as well as in the transport and automotive sectors – everything is possible with us.

Lightweight, electric and safe

Our structural components and chassis components made from crash alloys provide safe yet lightweight components that extend the range of electric cars, increase energy efficiency and enhance driving safety.

Industry solutions

E-mobility

Battery infrastructure, pressure plates, tie rods

Structural components

Seat cross-members, hybrid rear floor and strut welded assemblies, hybrid cross-members

Construction industry

Intelligent facade systems, functional surfaces, flood protection, windows, swimming pool roofing, sun protection, balcony systems, sunrooms and more

Home interior and office equipment

Desk feet, partitions, office furniture, door closer blank, interior decoration, cable channels and more

Mechanical and electrical engineering

System profiles, machine components, guides, heat sinks, high/low voltage fittings and control boxes, generators, motors, control units

Value chain

Value chain

Through our deep value chain, we manufacture a wide variety of aluminum products for you. Whether individual components, small welded assemblies, aggregates up to large modules, we develop the best solutions in close cooperation with our customers. Our highly automated production line with in-line measurements guarantees the highest component quality.

Complex further processing

Whether components or assemblies – we refine your profile into ready-to-install components. With precise high-performance saws, state-of-the-art CNC machining centers and welding cells, we cover all the work steps right up to the finished surface. With our facilities for further processing in Austria and Slovakia, and in close cooperation with renowned partners, we can provide you with an economical and efficient offer.

Integrated processing

Sawing, milling, punching, embossing, drilling, turning, bending, welding, surface treatment (anodizing, powder coating, pickling passivation, KTL), engraving, setting fasteners, brush burrs, barrel finishing, and more...

Profiles

The profile is the basic product of our direct extrusion plant in Marktl, Austria. We offer a very wide range of high-precision cross-sections with tight tolerances as well as multifunctional profiles, special applications with special material properties (e.g. bendable, crimpable) and functional applications (e.g. cooling fins for heat dissipation in lighting fixtures).

For our customers in the automotive sector, we offer a wide range of OEM-approved materials:

BMW according to GS 93047

STD-T1

WS02002 Typ UA

STD

WS02002 Typ A

CRA-T1

WS02002 Typ UB

CRA

WS02002 Typ B

WS02003 Typ UA

WS02003 Typ A

HAST-T1

WS02003 Typ UB

HST

WS02003 Typ B

Daimler according to DBL1172

.10

DBL1172

.20

DBL1172

.30

DBL1172

VW bzw. Audi according to TL116

N20

TL116

C20

TL116

N24

TL116

C24

TL116

Surface treatment

We offer surface treatment in cooperation with our certified partners. A wide range of design options are available (natural and colored anodizing, coating, mechanical surface finishing, washing, laser engraving, implementation of special surface requirements).

Products in record time

Products in record time

We manufacture approx. 33,000 tons of aluminum profiles per year with our direct extrusion presses, maintain long-standing customer relationships, and distinguish ourselves by our fast and flexible way of acting. From inquiry to tooling technology and metallurgical testing to the finished product, we manage the product introduction process in record time!

The direct extrusion process

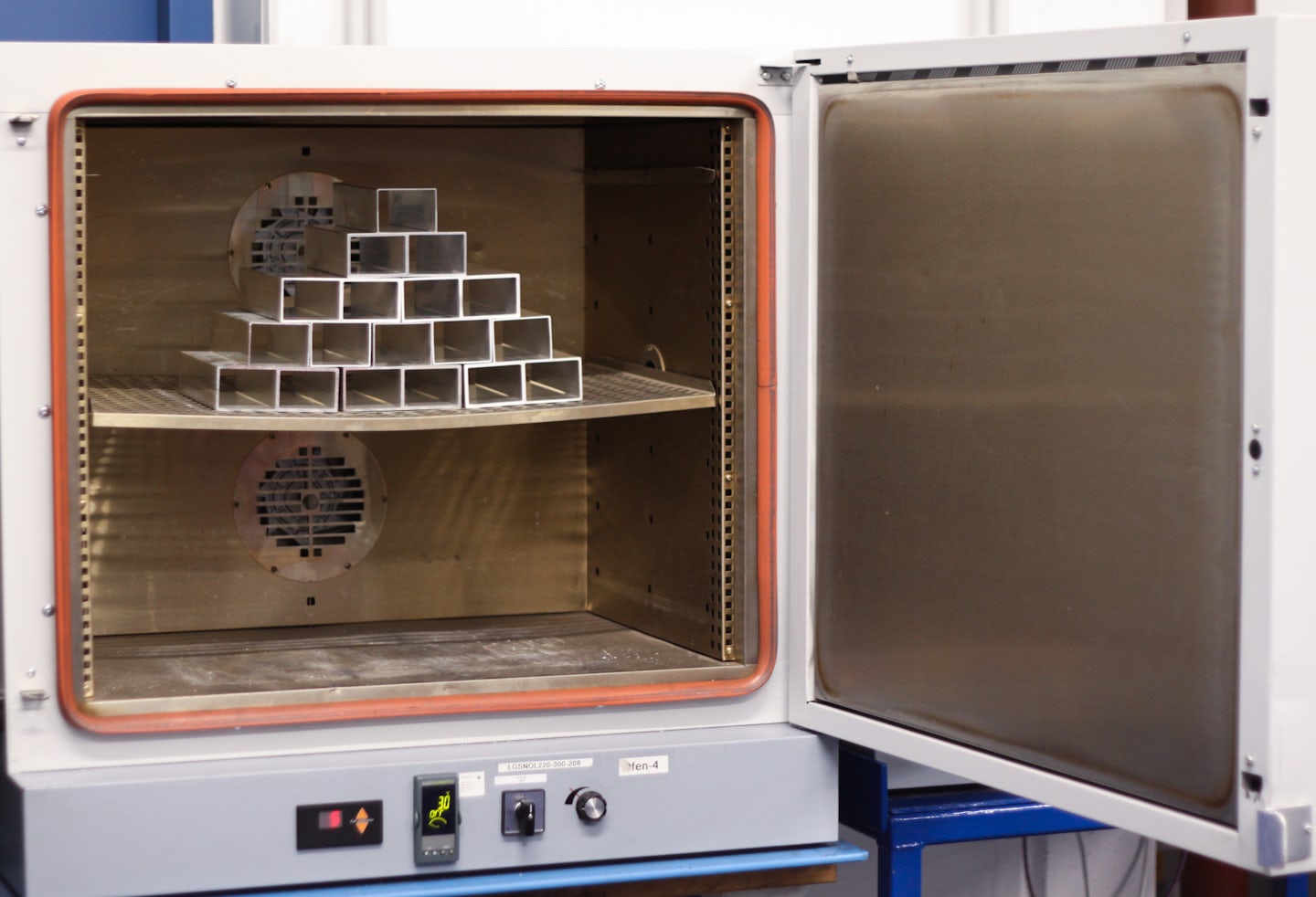

1. Heating

The material is heated to approx. 450 °C (approx. 840 °F).

2. Pressing

With a force of approximately 2,500 t, the aluminum is pressed through the extrusion die.

3. Cooling and cutting to length

The profile is cooled and cut to the desired length after forming saw packs.

4. Heat treatment and testing

In the final step, the material is brought to the desired strength by appropriate heat treatment. If necessary, a laboratory test follows.

The direct extrusion process

1. Heating

The material is heated to approx. 450 °C (approx. 840 °F).

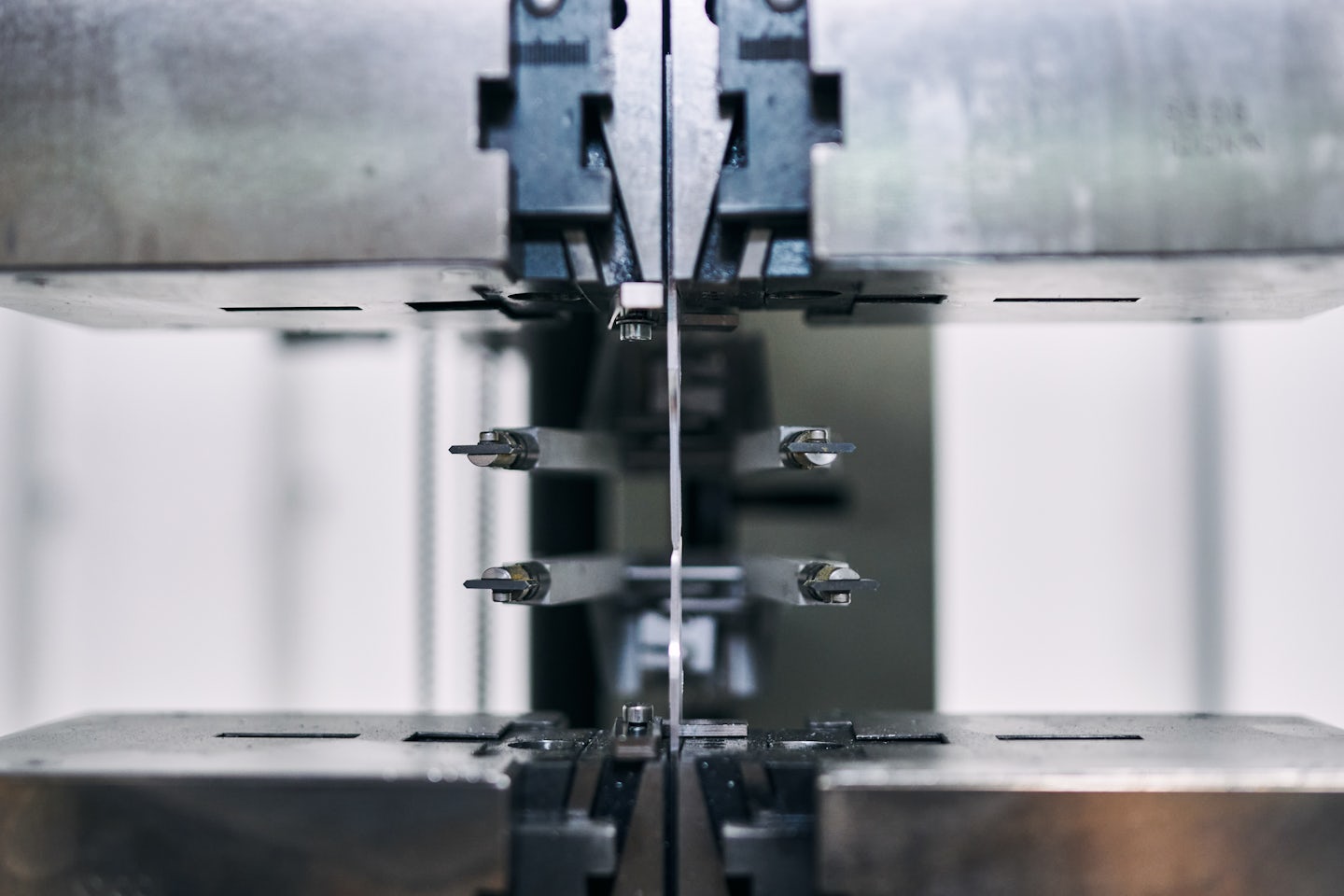

2. Pressing

With a force of approximately 2,500 t, the aluminum is pressed through the extrusion die.

3. Cooling and cutting to length

The profile is cooled and cut to the desired length after forming saw packs.

4. Heat treatment and testing

In the final step, the material is brought to the desired strength by appropriate heat treatment. If necessary, a laboratory test follows.

Highest quality standards

Simulation of heat treatment processes

By simulating heat treatment processes, we check their effects on the material properties and microstructure of our products.

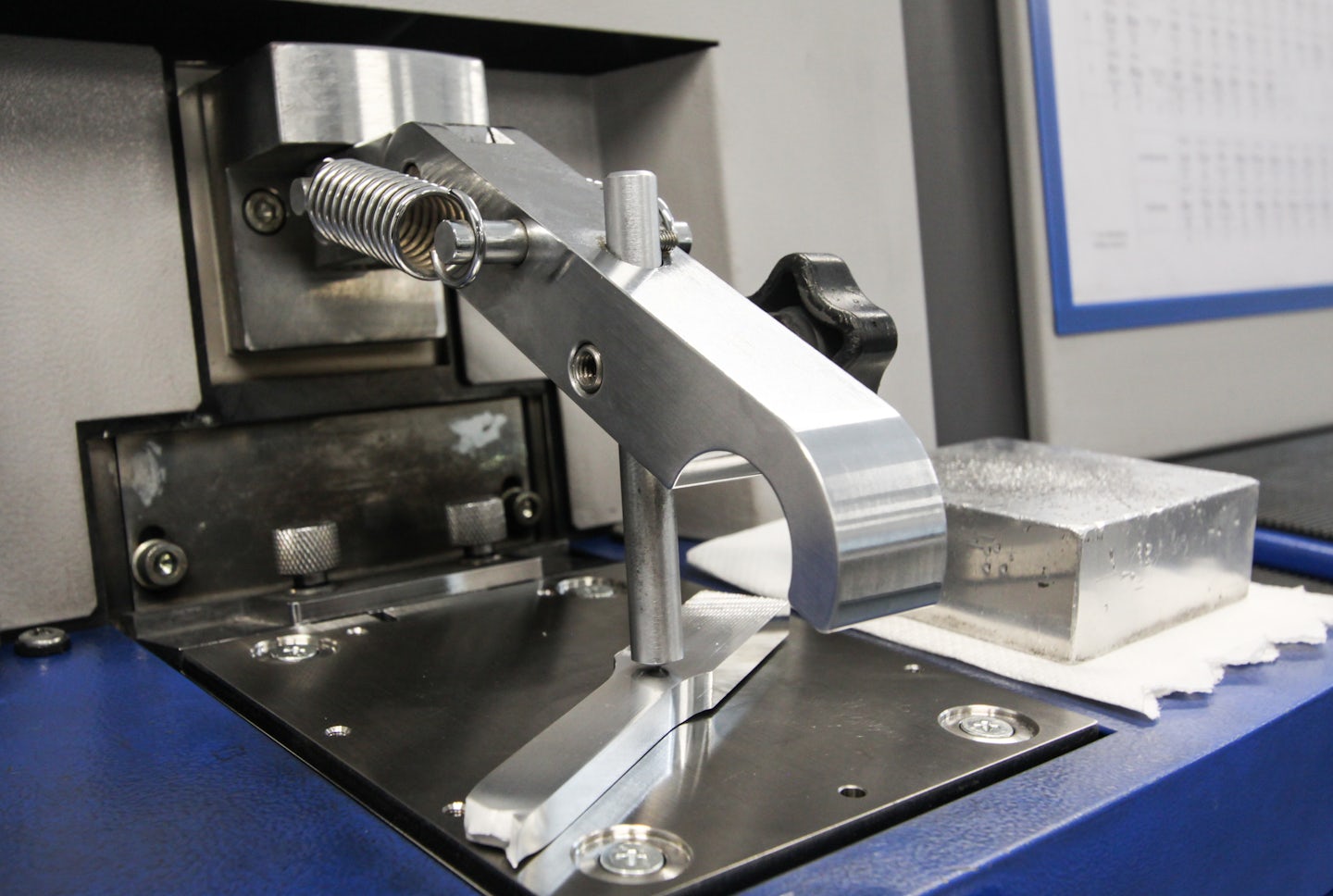

CNC machines

Testing machines and specimen preparation on modern CNC machines enable us to determine many technologically relevant mechanical characteristic values.

Metallography

Preparation of samples with state-of-the-art equipment for visualization of the microstructure and its characterization, damage analysis by fracture pattern analysis, scanning electron microscopy.

Corrosion tests

These are carried out according to automotive standards.

Spark spectroscopy

Checking and ensuring the chemical composition of the aluminum alloys used.

Locations and Certificates

At our production sites in Austria (Marktl) and Slovakia (Žarnovica), we collaborate with customers to develop solutions that optimally meet their requirements both technologically and economically. We have the expertise, experience, capacity and technical equipment to produce precisely machined and finished aluminum profiles in the desired time and quantity. We are certified according to the following standards: ISO 9001, ISO 14001, ISO 45001, IATF 16949, AEO, EN 15088.

Work for Neuman Aluminium

Work with us on cross-industry innovations!